Considerations for label overlays

NOTE: Creation of ZPL output in InterForm400 requires purchase of the ZPL module or the classic package.

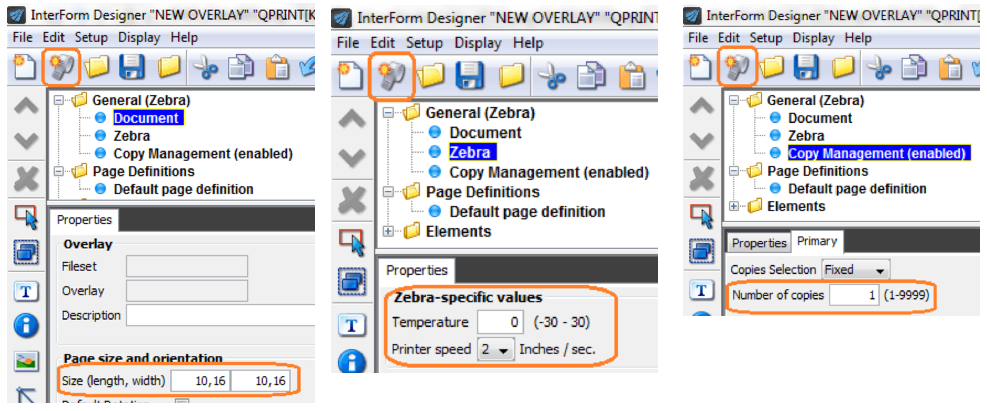

For overlays intended to be used for label printers the Design Overlay screen looks like this:

The especially label/Zebra related parameters are:

Page size:

The length and width of the labels to print on.

Temperature:

The temperature to use for the printing head. This number is a relative value (-30 to 30) for the temperature to use for the print head of the Zebra printer. This value will be added to the Darkness value specified on the printers display. That is if Darkness is 10 and temperature is 5 the actual Darkness value for merges with this overlay will be 15. If the sum of temperature and Darkness is outside the range 0-30 the nearest value is used.

Printer speed:

Specify the printing speed in number of inches per second. Note, that the highest possible print speed varies from one model to another.

Copy Management:

For label printers the number of copies can be up to 9999. If you set the number of copies to 9999, then the printer will print the same label indefinitely.

The Ink element is not supported for label file sets. To print something in white on black you just print in the same place twice in the same place.

Remember to create your overlays in a file set that fits the required output: A file set is intended for either PCL/PDF output or ZPL/IDP (IDP=Intermec Direct Protocol) output.

The fonts and images must be created/installed specifically for Zebra/Intermec.

Special printer types are also used for Zebra/Intermec output.

TIP: If you want to insert text, frames or images in reverse i.e. white on black background you can do it by first adding a frame with black filling (=pattern) and then place the text or image on top of the black frame (without specifying white in an Ink command). In this manner you reverse the part of the text or image, that overlaps the black frame.

NOTE: Make sure, that the label length stated is correct. If not this will affect the positioning of elements placed with rotation 90 and 270.

WARNING: Use a relatively low temperature e.g. 0 in order to avoid burn through of the ribbon and potential damage to the print head. The wear of the print head increases when using a higher temperature (or using a lower distance between paper and print head).

TIP: The print speed and temperature are related i.e. a higher speed might require a higher temperature and for lower speeds a lower temperature may be sufficient. J TIP J Regarding barcode printing on label printers: If possible it is a good idea to place the lines of the bars parallel with the traveling direction of the paper. In such a setup the print head will not need to cool off and heat up for each bar thus making it possible to print faster and use a lower temperature/Darkness setting.