InterForm400 can prepare the printed output for inserter machines by adding special OMR (Optical Mark Recognition) marks or barcodes in the margin of the printed output.

This will tell the inserter machines which pages, that belong together and should be put into the same envelope.

The configuration of the marks is setup via these menu option:

5. Work with Auto Forms Control

4. Finish Definitions

Here can you create inserter definitions if you press F6=Add and select type: 03:

Create Finish Definition PRS310D

Definition name . . . . . . INSERTER Description . . . . . . . . My inserter definition

Type of Finishing . . . . . 03 01 = Prinserter 02 = Stapling per Recipient 03 = Prepare for inserting 04 = PFE Mail-Printer 05 = Prepare for email/Fax 06 = PDF Filenaming 07 = Reformat Spooled File 08 = XML definition (classic version) 09 = XML+ definition (XML module required)

F3=Exit F12=Cancel

|

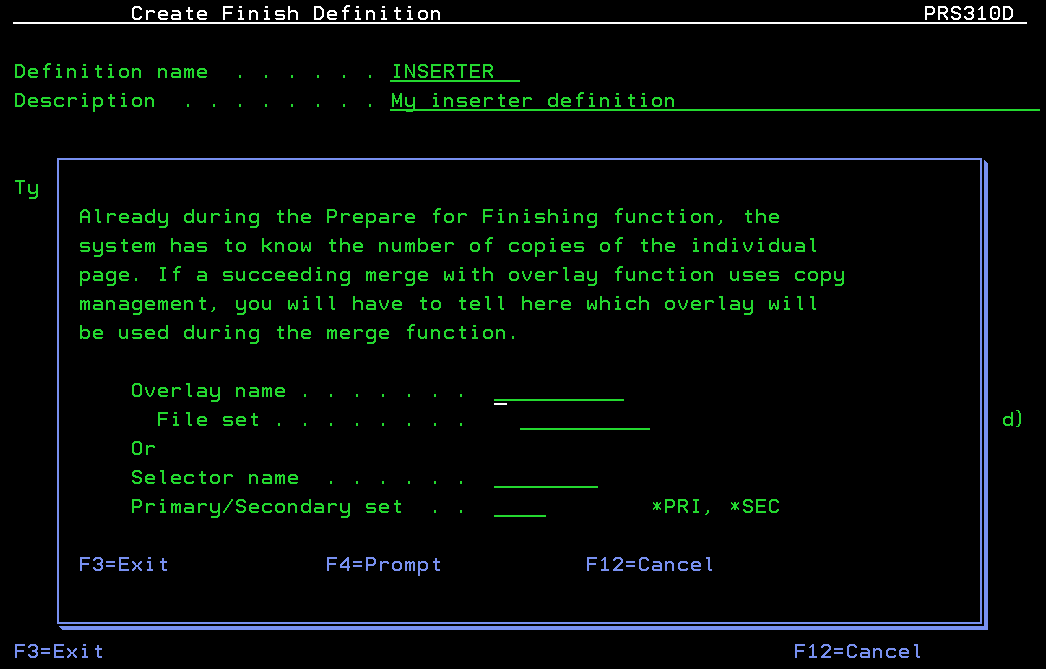

You then need to tell InterForm400 which overlay or overlay selector you will use for the merge, so InterForm400 can handle copy management if used:

Supported inserter machines are:

01 = Pitney Bowes OMR

02 = PFE Minimailer 2/3 Plus

03 = BÖWE OMR

04 = Neopost SI 68/72/76

05 = Pitney Bowes BARCODE

06 = PFE Automailer-2

07 = Bell+Howell

08 = Pitney Bowes OMR for DI380

09 = Neopost BARCODE

10 = NEOPOST 100/140 OMR

There are quite a few settings on the inserter definition in InterForm400, and it is very important, that these settings fits the settings of the inserter machine, that you intend to used.

The actual configuration differs a bit from machine to machine, but the setup is overall quite common, so as an example we can take a deeper look at a difinition based on 10 = NEOPOST 100/140 OMR:

Like for the most of the inserter machines this definition will add some lines in the margin of the final, merged output. Each line can be thought of as a marker or a binary flag:

Update Finish Definition PRS310

Inserting equipment . . . : NEOPOST 100/140 OMR

Controlling use of optical marks Gate mark will always be used.

Group multi-page documents . : 1 1 = Mark on last page in group 2 = Mark on all pages except last 3 = Mark on first page in group 4 = Mark on all pages except first

Parity mark . . . . . . . . : 1 = Odd parity 2 = Even parity 3 = Not used, space left blank 4 = Not used, no space used

F3=Exit F12=Cancel

|

Group multi-page documents

On the screen above we define the function of the Group multi-page flag: When should that line be shown?

Parity mark

You can chose, if there is a marker for parity and if what it should indicate if used. You can also reserve space for it (without using it) with 3= Not used,, space left blank.

Update Finish Definition PRS310D

Inserting equipment . . . : NEOPOST 100/140 OMR

Controlling use of optical marks

Selective feeding station 2 : 1 = Not used, space left blank 2 = Not used, no space used

Selective feeding station 3 : 1 = Not used, space left blank 2 = Not used, no space used

Form sequence within job . . : 0 0 - 6 MARKS) No zero . . . . . . . . : 0=Zero not used, 1=Zero used

Divert . . . . . . . . . . . : 1 = Not used, space left blank 2 = Not used, no space used

F3=Exit F12=Cancel

|

On the screen above these features can be set:

Selective feeding station 2

State if InterForm400 should reserve space for this or not. The function is not supported in InterForm400.

Selective feeding station 3

State if InterForm400 should reserve space for this or not. The function is not supported in InterForm400.

Form sequence within job

For many of the inserter machines you can define a binary counter via the output lines. This counts the total number of pages (for some machines you can tell InterForm400 to count down). Here you set the number of bits (or lines) in the counter, and define if zero as a value for the binary counter is used or not.

Divert

State if InterForm400 should reserve space for this or not. The function is not supported in InterForm400.

Update Finish Definition PRS310D

Inserting equipment . . . : NEOPOST 100/140 OMR

Controlling use of optical marks

No seal . . . . . . . . . . : 1 = Not used, space left blank 2 = Not used, no space used

Form sequence within group . : 0 0 - 4 MARKS No zero . . . . . . . . : 0=Zero not used, 1=Zero used

Distance between marks . . . : 1=1/8" 2=1/6" 3=1/5" 4=1/4" 5=1/3" 6=3mm 7=5mm

Max pages in an envelope . . : 0

Max envelopes to a recipient : 0

Formtype output to inserter : Formtype > max envelopes . :

F3=Exit F12=Cancel

|

No seal

State if InterForm400 should reserve space for this or not. The function is not supported in InterForm400.

Form sequence within group

For many of the inserter machines you can define a binary counter via the output lines. This counts the pages for the current envelope (for some machines you can tell InterForm400 to count down). Here you set the number of bits (or lines) in the counter, and define if zero as a value for the binary counter is used or not.

Distance between marks

Here you can decide the distance between the OMR lines in the printed output.

Max pages in an envelope

The maximum number of pages, that is allowed inside each envelope.

Max envelopes to a recipient

If there are more pages, than one envelope can hold, then InterForm400 will distribute the pages into multiple envelopes, but here you can also state a limit of how many envelopes, that InterForm400 can create for a single document.

Formtype output to inserter

The result of the Inserter finish definition is a new spooled file. This should normally be merged into a new spooled file in Auto Forms Control.

Formtype > max envelopes

If a document contains more pages, than what is allowed in the max. number of envelopes, then the pages for those documents are output in a separate spooled file. This makes it possible to separate the pages, that can be inserted into envelopes from the pages containing the very large documents, that cannot fit in envelopes. (They are probably printed and shipped in a box or even as a PDF file).

Update Finish Definition PRS310D

Inserting equipment . . . : NEOPOST 100/140 OMR

Placement of optical marks Rotation . . . . . . . . 000 From top edge . . . . . 1,000 From left . . . . . . . 1,000

F3=Exit F12=Cancel

|

On the screen above you state where the OMR lines are to be printed.

As the final thing we need to tell InterForm400 how to identify each document via a document number e.g. invoice number or even customer number.

You can create one or multiple sequence lines. Normally one is enough, but if the document number moves around from page to page, then you need one sequence line for each position:

Work with Finish Recipient-ID PRS320D

Definition name . . . . : INSERTER

Start with . . . . .

Type option, Press Enter. 2=Change 3=Copy 4=Delete 5=Display

Opt Seqnbr. Description 001 All pages - demo splf

End F3=Exit F5=Refresh F6=Add F12=Cancel

|

A sequence line can be defined like below for the InterForm400 demo spooled file to refer to the 4 digit number in line 13 positions 57-60:

Update Finish Recipient-ID PRS330D

Definition name . . . . : INSERTER

Sequence number . . . . : 1 Description . . . . . . . All pages - demo splf

Page selection criteria Print line Position Oper Compare value - - -

Find recipient ID in the following positions Print line Position 13 57 - 60 - - - - - F3=Exit F12=Cancel F13=Select spooled file

|

If the document number is missing on some pages or moving around, then you can use the page selection criteria above (and perhaps even multiple sequence numbers) to handle that.

Implementing the OMR finish definition

To put the OMR finishing definition into production you need to use the C=Prepare for Finish definition function in Auto Forms Control.